Providing Next

Generation & Sustainable WasteWater Treatment

Solution through Innovative & Efficient Product & Services

Why Traya Hydrotech

Traya Hydrotech as part of Traya Hydro & Co. is a total water solution provider that delivers Plug & Play WasteWater Solution using Membrane Bioreactor (MBR) and Ultrafiltration system as Game Changing Technology in Water and Wastewater Treatment Industry.

We focus on customer Solution by providing cost effective, high quality and sustainable water treatment system with our proprietary water treatment product.

Our Advance Products is ranging from Modular WWTP/STP system and Containerized STP. Our System can be also CUSTOMIZED to meet the customer’s need by altering its configuration and operation parameter.

Our company is also a high-tech enterprise focusing on the R&D, production, manufacturing and service of Membrane Bioreactor (MBR) & Ultrafiltration Membrane (UF) products that has many years of experience in designing innovative membrane bioreactor (MBR).

Our Vision

We are envisioned to create Positive Impact for a better living to the community by providing High Quality Waste & Water Treatment Solution through Innovative & Efficient Product & Services.

Why Membrane Bioreactor (MBR)?

Membrane Bio-Reactors (MBR) have become recognized as a state-of-the-art wastewater treatment technology because of It can purify wastewater to produce the highest effluent water quality.

One of the many benefits of an MBR system is that it effectively overcomes the issues of poor settling flocs in conventional activated sludge as all treated wastewater is discharged via the membrane.

The Bio microbe MBR process therefore will always result in a very high quality of treated water that is virtually solids free.

MBR technology is increasingly popular in Indonesia for industrial wastewater treatment due to its small footprint, reliably and the ability for re-using wastewater.

Our Solutions

-

We specialize in designing, manufacturing and commissioning of package plants for wastewater treatment using Membrane Bioreactor (MBR).

Wastewater Treatment (WWT) process is removing contaminants from wastewater or sewage and convert it into an effluent that can be returned to the water cycle with acceptable impact on the environment. The treatment process takes place in a Wastewater Treatment Plant (WWTP) and it also refers to as Water Resource Recovery Facility (WRRF) or Sewage Treatment Plant (STP) in the case of domestic wastewater. Pollutants in wastewater are removed, converted, or broken down during the treatment process.

Wastewater can be upgraded to process or portable water standards. Our team will assist municipalities and industries to reduce their reliance on increasingly undependable natural water sources and produce environmentally safe effluent and solid waste that can be reused for a variety of applications.

Our industrial MBR water treatment plant offers smaller footprint, Higher Treatment Efficiency, Lower Cost, Easy Construction & Operation, and environmentally friendly. A fully containerized wastewater treatment plant package is available to meet client requirements.

Advance technologies and processes for industrial wastewater treatment applied in our wastewater system provide solution for your industrial wastewater treatment requirements.

-

We provide operation and maintenance services for commercial, industrial, municipal water and wastewater treatment tailored to your requirements.

We will ensure that your dosing stations are maintained in optimum working condition and that dosing system is executed as required so that your plant consistently operates to specification.

-

As one of the cornerstones of our core business, we design, build, own and operate complete turnkey filtration systems based on our proprietary membrane technology to address customer's needs.

•We provide DBOO services to enable customers to focus on their core businesses.

•We provide highly trained engineers to maintain a constant supply of processed water for our customers.

•We ensure continuous innovation of our proprietary filtration membrane technology to meet new industrial requirements.

•We are committed to service an ever-growing list of local and overseas customers.

Our Products

Plug & Play Factory Built Wastewater Solution

-

Scalable: Our modular systems can expand as capacity requirements change – and be redeployed at the end of a temporary project if necessary

Reduced On-Site Construction: Modular systems are pre-plumbed, pre-wired and undergo comprehensive testing, allowing for fast installation and minimized on-site work.

Minimal Maintenance: Air scouring and periodic membrane relaxation prevent fouling; chemical cleaning is reduced over hollow fiber membranes.

Operator-Friendly: Our ground-level module removal system is good example of the design considerations we incorporate for easy servicing and improved safety.

-

The Cutting-Edge Technology: The Containerized STP is an ingenious wastewater treatment solution, skillfully packed into a compact modular container. Based on the advanced Membrane Bioreactor MBR) technology.

Space-saving and Easy Transportation: With limited space becoming a pressing concern, the Containerized STP comes to the rescue by optimizing the treatment process within a single container. This innovative design not only saves space but also facilitates seamless transportation.

Seamless Installation and ‘Plug & Play’: The beauty of the Containerized STP lies in its preinstalled and factory-tested sewage treatment equipment. As a result, on-site installation work is minimal, adopting a straightforward ‘Plug & Play’ approach

-

We specialize in designing Customized WasteWater treatment solutions, using our Plug & Play Modular System, to meet specific client needs and project requirements.

Our team of engineers and specialists works closely with customers to analyze water characteristics, assess treatment goals, and propose optimized solutions. From initial feasibility studies to system commissioning and ongoing support, we ensure seamless project execution and long-term performance.

Membrane Products

-

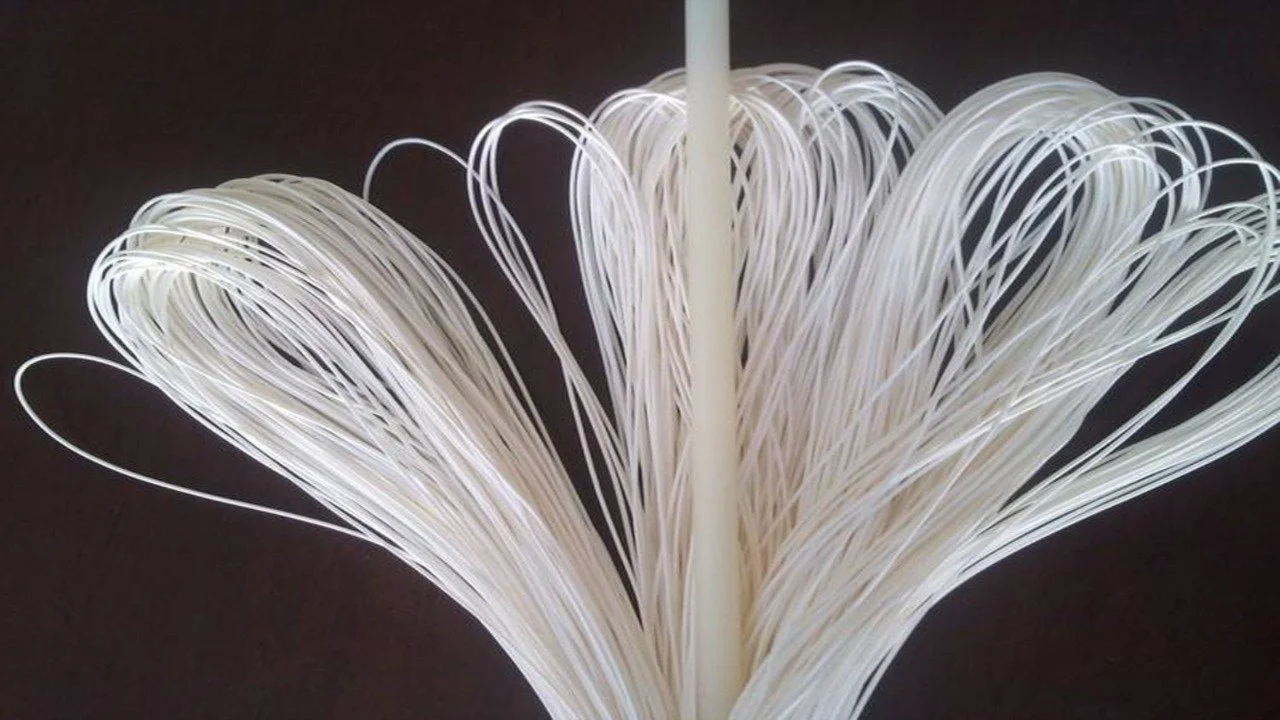

To streamline industrial production and installation processes, enhance the efficiency of hollow fiber membranes, and maximize the membrane area per unit volume, it is common practice to assemble hollow fiber membranes into a primary unit device.

This device facilitates the separation of components in a mixture under specific driving forces and is known as a hollow fiber membrane module. For instance, our membrane module is a submerged module specifically designed for MBR systems.

-

Our-reinforced PVDF hollow fiber curtain membrane incorporates traditional curtain membranes’ merits from domestic and international sources.

Furthermore, it adopts a bundled curtain structure that offers high filling density, compact layout, and space-saving benefits. It ensures uniform and efficient aeration, prevents the accumulation of pollutants, and facilitates easy maintenance and replacement